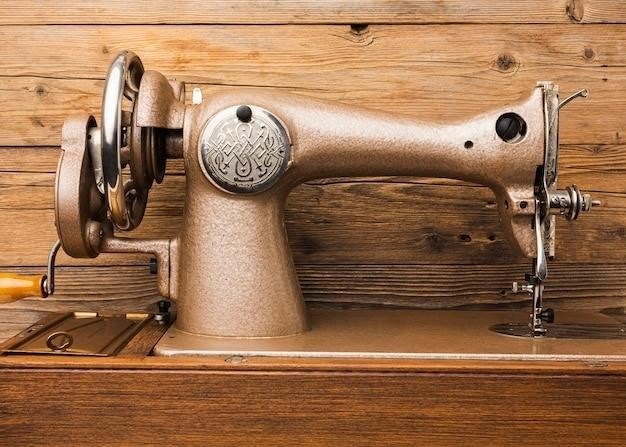

Singer Manual Machine⁚ A Comprehensive Guide

This guide provides a complete resource for finding and using Singer sewing machine manuals. Locate your manual online through free downloads or databases‚ or order a hard copy. Learn about specific models like the 1116‚ 28k‚ and 4411‚ and utilize official Singer channels for assistance. Ensure you have the correct manual for safe and effective operation.

Finding Your Singer Manual

The first step in utilizing your Singer sewing machine effectively is locating its manual. Begin by thoroughly searching your home. Check common storage areas such as drawers‚ shelves‚ and boxes where you might keep instruction booklets for appliances. Look for a Singer-branded manual‚ possibly containing your machine’s model number. If the manual isn’t immediately found‚ don’t despair; numerous online resources and offline options exist to assist you. Remember to check for any accompanying paperwork when purchasing a used sewing machine‚ as a previous owner might have retained the manual. If you’re unsure of your machine’s model number‚ examine the machine itself; it’s usually printed on a visible label. This number is crucial for finding the correct manual. Having the model number readily available will significantly expedite your search‚ whether online or through official Singer channels.

Locating Manuals Online⁚ Free Downloads and Databases

The internet offers a wealth of resources for finding Singer sewing machine manuals. Many websites specialize in providing free downloads of manuals for various Singer models. These sites often categorize manuals by model number‚ making it easy to find the specific instructions you need. Before downloading‚ ensure the website is reputable to avoid potential malware or incorrect information. Several online databases also index Singer manuals‚ offering searchable catalogs. These databases may link directly to downloadable PDFs or provide links to relevant websites. Remember to carefully check the model number listed on the manual to ensure compatibility with your machine. Always verify the authenticity of the downloaded file by checking the source and ensuring it matches your machine’s model number. Be cautious of sites offering manuals for a fee unless you’re confident in their legitimacy. Exploring multiple sources increases your chances of finding the accurate and free manual for your Singer sewing machine.

Singer Manuals for Specific Models⁚ 1116‚ 28k‚ 4411‚ and Others

Singer produced a vast array of sewing machine models over the years‚ each with its own unique manual. Finding the correct manual for your specific model is crucial for safe and effective use. Popular models like the 1116‚ known for its simplicity‚ and the 28k‚ a vintage workhorse‚ have dedicated online communities and resources where users share manuals and troubleshooting tips. The 4411‚ a heavy-duty model‚ often requires specialized instructions for its powerful motor and features. When searching online‚ always include the full model number to avoid confusion. Some models may have slight variations even within the same series‚ so double-checking the serial number (if available) can help pinpoint the exact manual. Remember‚ using the wrong manual can lead to improper operation‚ potential damage to the machine‚ and even safety hazards. Therefore‚ investing time in locating the precise manual for your specific Singer model is essential.

Accessing Manuals Through Official Singer Channels

Singer‚ as a major sewing machine manufacturer‚ offers various avenues for accessing official manuals. Their website often features a dedicated section for downloading manuals‚ often searchable by model number. This is the most reliable source for ensuring you get the correct‚ up-to-date instructions for your specific machine. However‚ the availability of manuals online may vary depending on the age and model of your machine; older models may not have digital versions readily available. If the online resources prove insufficient‚ consider contacting Singer’s customer support directly. Their representatives can assist in locating the manual or provide alternative support channels. They might offer a paid hard copy service or point you towards authorized dealers who may have access to archived manuals. Alternatively‚ explore the possibility of contacting Singer’s corporate offices; they could potentially direct you to an archive or provide assistance in locating a suitable manual. Remember to have your model number and serial number (if available) ready when contacting them for efficient service.

Hard Copy Manuals⁚ Ordering Options and Availability

While digital manuals are convenient‚ some sewists prefer the tangible experience of a hard copy. Several options exist for obtaining a physical Singer sewing machine manual. Singer’s official website may offer a direct ordering service for manuals‚ although availability can vary depending on the model and age of your machine. Older models might be harder to find‚ and some might not be available at all. Check the website for current offerings and pricing. Alternatively‚ consider contacting authorized Singer dealers or repair centers. These businesses often stock common manuals or can order them on your behalf‚ potentially offering a quicker turnaround than ordering directly from the manufacturer. Online marketplaces like eBay or Amazon might also list used or new Singer manuals‚ but be cautious when purchasing from these sources; verify the seller’s reputation and ensure the manual is compatible with your machine’s model number. Finally‚ consider checking local libraries or antique shops; occasionally‚ older manuals might be available through these avenues. Remember to always confirm compatibility before purchasing.

Importance of Using the Correct Manual

Using the correct Singer sewing machine manual is paramount for safe and effective operation. Each Singer model‚ even those within the same series‚ may have unique features‚ adjustments‚ and safety protocols. A mismatched manual could lead to incorrect operation‚ potentially causing damage to the machine‚ your fabric‚ or even resulting in injury. The specific instructions for threading‚ stitch selection‚ bobbin winding‚ needle changes‚ and maintenance procedures differ across models. Following the wrong instructions can lead to frustration‚ wasted time‚ and unnecessary repairs. The correct manual ensures you understand the specific capabilities and limitations of your machine‚ preventing accidental misuse. Furthermore‚ safety precautions are model-specific‚ and incorrect procedures could cause serious harm. Proper maintenance instructions ensure the longevity of your machine. Therefore‚ always cross-reference your machine’s model number with the manual to guarantee a perfect match before beginning any sewing project or maintenance task. Taking the time to find the correct manual is an investment in the safety and longevity of your sewing experience.

Safety Precautions When Using a Singer Sewing Machine

Operating a Singer sewing machine safely requires careful attention to detail and adherence to specific precautions. Always unplug the machine before cleaning‚ oiling‚ or making any adjustments. Keep fingers and other body parts away from moving parts‚ especially the needle and presser foot area. Use the appropriate needle and needle plate for your fabric type to avoid needle breakage and potential injury. Never leave a running machine unattended. Before starting‚ ensure the machine is properly grounded to prevent electrical shocks. Children should be supervised at all times around the sewing machine‚ and the machine should never be treated as a toy. Always use the correct speed for the task at hand‚ avoiding overly rapid sewing that could lead to accidents. Proper lighting is crucial to prevent eye strain and ensure safe operation. Regularly inspect the power cord and electrical connections for damage. If any damage is found‚ immediately cease operation and have the machine checked by a qualified technician. Remember‚ careful handling and attention to safety measures will help avoid accidents and ensure a pleasurable sewing experience.

Understanding Your Machine’s Features⁚ Stitch Types and Functions

Singer sewing machines offer a variety of stitch types and functions‚ catering to diverse sewing needs. Familiarize yourself with the different stitch options available on your specific model‚ consulting the manual for detailed explanations. Basic stitches include straight stitch‚ zigzag stitch‚ and various decorative stitches. Many models also provide specialty stitches such as buttonholes‚ blind hems‚ and stretch stitches. Understanding stitch length and width adjustments is crucial for achieving the desired results. Adjustments allow you to customize stitches for different fabrics and projects. Some Singer machines feature automatic needle threading‚ simplifying the setup process. Others may include features like adjustable presser foot pressure‚ enabling you to work with a wide range of fabric weights. Learn how to utilize the reverse stitch function for securing seams and reinforcing areas. Explore the various feed dog settings to control fabric movement during sewing. Mastering your machine’s stitch types and functions unlocks its full potential‚ allowing you to tackle a wider array of sewing projects with confidence and precision.

Troubleshooting Common Issues with Singer Machines

Encountering problems with your Singer sewing machine? Don’t panic! Many common issues have simple solutions. If your machine isn’t powering on‚ check the power cord and outlet. A jammed needle is a frequent problem; carefully remove the broken needle and replace it with a new one‚ ensuring it’s correctly inserted. If the stitches are skipping‚ inspect the needle for bending or damage. Also‚ check the thread tension; incorrect tension can lead to skipped stitches or uneven fabric feeding. A tangled thread often requires careful untangling from the bobbin area and needle. If the machine is making unusual noises‚ it might need lubrication. Consult your manual for specific lubrication instructions. Difficulty feeding fabric could be due to a clogged feed dog or incorrect presser foot pressure. Clean the feed dog area thoroughly. If the bobbin case is improperly installed‚ it can cause problems with the stitch formation. Ensure the bobbin case is correctly placed and that the bobbin is properly wound. For persistent issues‚ refer to your machine’s manual or contact Singer customer support for assistance. A little troubleshooting often resolves minor sewing machine problems quickly.

Maintaining Your Singer Machine⁚ Cleaning and Lubrication

Regular cleaning and lubrication are crucial for maintaining your Singer sewing machine’s optimal performance and longevity. Begin by unplugging the machine from the power source. Use a soft brush or compressed air to remove lint‚ dust‚ and thread scraps from the bobbin area‚ feed dogs‚ and other accessible areas. Pay close attention to the shuttle area and needle plate‚ as these tend to accumulate debris. A soft cloth slightly dampened with a mild cleaning solution can be used to gently wipe down the exterior surfaces. Avoid using harsh chemicals or abrasive cleaners‚ as these could damage the machine’s finish; For lubrication‚ consult your machine’s manual for recommended lubricants and application points. Typically‚ a high-quality sewing machine oil is used. Apply only a small amount of oil to designated lubrication points‚ avoiding excessive oiling. After lubricating‚ run the machine for a short time to distribute the oil evenly. Regular maintenance‚ including cleaning and lubrication‚ helps prevent mechanical problems‚ ensures smooth operation‚ and extends the life of your valuable Singer sewing machine. Remember to refer to your manual for specific instructions and recommended cleaning schedules.

Needle and Needle Plate Considerations

Selecting the correct needle and needle plate is paramount for achieving optimal sewing results and preventing damage to your Singer sewing machine. The type of needle you choose depends on the fabric you’re sewing. Using the wrong needle can lead to skipped stitches‚ broken needles‚ or damage to the fabric. Consult your machine’s manual for a comprehensive guide on needle selection based on fabric weight and type. Always ensure the needle is correctly inserted and tightened securely. A bent or damaged needle should be replaced immediately. The needle plate‚ located beneath the needle‚ plays a crucial role in guiding the fabric and ensuring even stitch formation. Using the incorrect needle plate can result in needle breakage and uneven stitches. Your machine’s manual will specify the correct needle plate for various sewing tasks. It’s essential to use the correct needle plate for the type of needle you’re using. Never force the needle through the fabric; if the needle breaks‚ immediately turn off the machine and remove the broken needle carefully to avoid injury. Regular inspection of both the needle and needle plate for wear or damage is crucial for maintaining smooth sewing operation and preventing potential problems. Remember‚ proper needle and needle plate selection and maintenance contribute significantly to the longevity and optimal performance of your Singer sewing machine.

Resources for Further Assistance⁚ Customer Support and Online Communities

Beyond your Singer sewing machine manual‚ several resources offer valuable support and troubleshooting assistance. Singer’s official website often provides a comprehensive FAQ section‚ downloadable manuals‚ and contact information for customer support representatives. Their customer service team can address specific questions regarding your machine’s operation‚ maintenance‚ or repair needs. Many online forums and communities dedicated to sewing and Singer machines offer a wealth of collective knowledge; Experienced users share tips‚ tricks‚ troubleshooting solutions‚ and advice on various Singer models. These online communities can be invaluable for finding answers to common problems or seeking guidance on specific projects. Searching for your Singer machine’s model number on these platforms can often yield relevant discussions and solutions to issues you may encounter. Remember to always exercise caution and verify information obtained from online sources against your machine’s manual and official Singer documentation. In addition to online forums‚ you may find helpful videos and tutorials on platforms like YouTube that demonstrate specific techniques or troubleshooting steps. By utilizing these various support resources‚ you can effectively address any difficulties encountered while using your Singer sewing machine and enhance your overall sewing experience.